Precoat filter

A bit of filter know-how

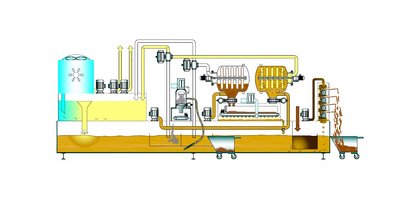

What is a precoat filter?

Precoat filters are used when the highest required filter fineness is coupled with difficult filtration properties. An example is the abrasion occurring in the grinding oil during the precision machining of cast materials. The grinding dust contains very finely distributed graphite which quickly leads to blockage of filter media. A filter cake with these fine particles is difficult to pass through and has a large pressure loss. Therefore, a cake-forming filtration would consume considerable energy here and would be very ineffective in this sense.

A precoat filter achieves its excellent filter properties through a process sequence. In the first step, a material which is easy to filter, the filter aid (e.g., cellulose, perlite or diatomaceous earth) is suspended in liquid and redeposited on a relatively coarse filter (e.g., a stainless steel sieve). The resulting filter cake, the precoat layer, serves as a filter medium in the second step. The filter aid is chosen in a way, that a very porous, easy-to-flow-through precoat layer is formed.

In the second process step, the actual filtration of the suspension takes place. Coarser particles settle on the surface of the precoat layer. However, the finest particles of the suspension can penetrate into the precoat layer and are deposited there in the pores. The pressure loss of the precoat layer initially only increases slowly. Only when a significant proportion of the pores in the precoat layer is filled with dirt particles, a significantly increased pressure loss occurs.

In the last process step, the suspension feed is stopped and the filter surface is cleaned.

Because of their special properties, precoat filters are also used – beside metalworking – in the beverage industry for the clarification of beverages such as beer and wine, among others.