Belt filter

A bit of filter know-how

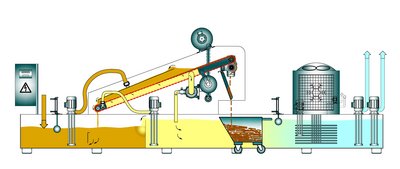

Belt filters

Belt filters use a flat filter belt of sieve fabric or filter fleece as a filter medium. The filter belt is acted upon with the suspension on its upper side and the liquid is discharged on the underside. As a rule, the filter medium is supported by a sieve bottom or a carrying belt on its underside. In order to discharge the separated solids, the filter belt is moved forward on the sieve bottom or with the carrying belt. The movement of the filter belt can take place continuously or intermittently (timed).

To accelerate the flow through the filter cake and the filter medium, either a negative pressure is applied on the underside (vacuum band filter, suction belt filter) or the space above the filter medium is subjected to pressure (pressure belt filter). In simple systems, only the static fluid pressure is used as the driving force (hydrostatic filter).

When the liquid above the filter cake has drained, the dehumidification of the filter cake begins. The higher the pressure difference between top and bottom, the lower the achievable residual moisture in the filter cake.

The filter belt may be an endless filter belt made of sieve fabric which is guided over rollers in a circle. Alternatively, filter fleece can be used, which is disposed of after use.